Periodically I am asked what my favourite wheel building tools are. Sometimes by new aspiring builders and sometimes by very seasoned ones. Being a self confessed tool junkie I have accumulated a noteworthy collection of job specific tools for most every type of wheel work.

All the various tools needed to turn all the numerous nipple types available today.

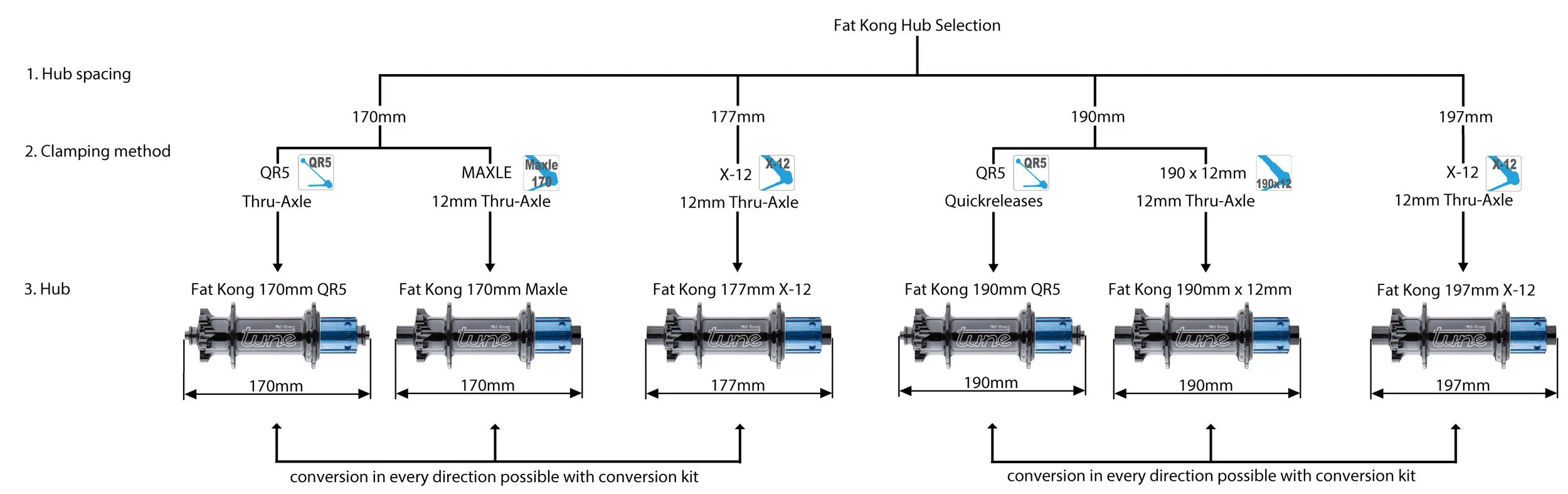

As the years have passed I've had to keep pace with all the new tools needed to do my job. For instance, with all the hubs currently available its no wonder that a sizeable collection of dedicated tools are required if you want to be able to service them all. Companies like Chris King make their own in house tools to service their hubs as well as several other manufacturers. The same could be said for the plethora of spoke wrenches and similar tools needed to just turn nipples, especially with the growing number of nipple interfaces available today.

A 5.5mm Hex head spoke nipple driver, made in California by Bicycle Research. Also the "Mulfinger' made by Efficient Velo Tools. An invaluable tool for lacing up wheels.

Though a more significant investment in quality tools is needed for the modern wheel builder, it will definitely make the job easier. When I first started out building wheels I had only a handful of tools. A single VAR chrome vanadium spoke key, a 1950's Campagnolo wheel dishing tool and a cast iron Hozan wheel truing stand that had acquired a patena that made it look like it had been dredged up from the ocean floor off the Titanic. Though I started with just a few wheel building tools I managed to master the art with some time and dedication. I worked with what I had. That was over 4 decades ago and things have changed! These days my work bench is cluttered with too many tools to count. New ones seem to arrive every month and the cycle continues.

A DT Swiss Tensio 2. One of a few spoke tension meters that I employ to measure spoke tension and to evaluate the overall evenness of a wheels final tension.

Spoke Tension

In the last few years builders have been paying more attention to a wheels precise spoke tension. As tension meters have increased in accuracy and sensitivity its enabled us to evaluate our wheels more closely. At first I was definitely reluctant to embrace spoke tension meters, but eventually I began to explore their use. In the last few years I have completely embraced them in my workflow. I have come to realise how they can be exploited in the initial stages of the building process, not just as an afterthought to determine the final finished tension of a wheel. This has fundamentally changed the way that I now build wheels. That's been a huge change in methodology for me, but a welcome one.

Recently I have been working with a friend to produce a high end spoke tension meter for Cognoscenti Cycles. Below is a photo of the prototype that has undergone extensive testing.

This is the prototype of the new Cognoscenti Cycles spoke tension meter for 2018. It comes with a Swiss made Atorn dial indicator, a CNC made 6082 alloy body and a THK linear roller bearing that enhances the accuracy and sensitivity of the meter.

The Truing stand

Certainly one of the most important tools for any wheel builder is their truing stand. There are several stands on the market these days and prices vary greatly as well as features. Since the late 1970's I have used a Park stand. It really hasn't changed that dramatically over the years. Yes, there have been a few notable additions but essentially the design remains much the same as the early days. As much as I have been tempted by a few new truing stands I have always returned to that Park stand. It basically does everything one needs and I guess that's all that matters. I briefly owned a DT Swiss truing stand. I quickly realised that even though it was incredibly well made, that old Park stand worked better for my work flow. I sent the DT Swiss stand back for a refund and re-embraced my Park stand. I went through a similar experience with the German made P&K Lie stand. For some builders this stand may be the ultimate, but not for me. There is a deep lesson to be learned here. You must use the tools that work well for YOU! In the end, you have to be both comfortable and confident with those tools. They shouldn't limit you in any way, but as long as you are able to turn out top quality wheels your tool choices are fine.

A DT Swiss spoke key and their bladed spoke holder. Designed to work perfectly together, these are my fave tools for building with bladed spokes.

The Campagnolo dishing tool made it's debut in 1952. I have used this tool since day one, and I still use it every day. Perfection is hard to improve upon.

I certainly haven't delved into every tool that one could possibly use while working on wheels. There are so many that if I did this article would turn into a small book. Suffice to say that there is a good tool for every task and investing in the best quality ones is wise. Knowing how to use them properly is of course the most important thing. There is no substitute for experience.